|

ACO Group improves global collaboration thanks to Teamcenter migrationBy Jens Steinbuß "ACO. We care for Water" is the guiding principle of the ACO Group. The world's leading water technology company has placed its existing Teamcenter installation on a new footing with the aim of standardizing engineering processes and making it easier to connect other ACO subsidiaries to the PLM solution. PROSTEP assumed responsibility for migrating the CAD and PLM data to the new system environment.

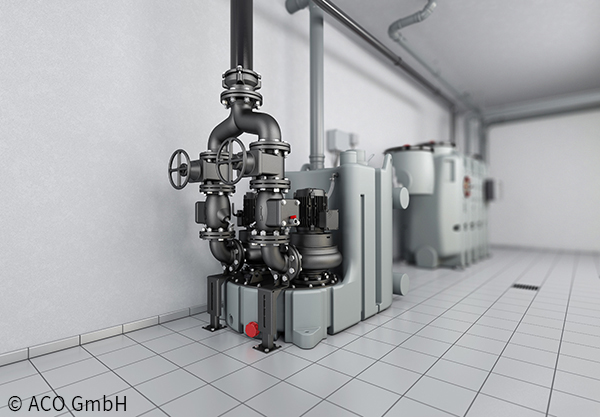

Everyone has walked over an ACO manhole cover or drainage channel at some point in their life, perhaps without even realizing it. ACO develops, manufactures and sells products and integrated solutions for the collection, storage, treatment and reuse of rain and wastewater. In addition to manhole covers and drainage channels, the company's range of products also includes drainage systems for traffic infrastructures and sports facilities, oil and grease separators, backflow stop systems, light shafts for cellars, system components for water management in the civil engineering sector, and wastewater treatment in shipbuilding. ACO has a workforce of 5,400 employees and is represented in over 50 countries. In 2023, the company generated revenues of over 1.1 billion euros. Chief Information Officer Dominik Neff points out that "ACO is a classic hidden champion – a family-owned company that operates globally but also has strong regional roots." Anyone not yet familiar with ACO's headquarters in Büdelsdorf, about an hour's drive north of Hamburg, may be familiar with NordArt – one of the largest adjudicated exhibitions of contemporary art in Europe. ACO is the host of this international art exhibition, which is displayed in the halls of the former Carlshütte iron foundry and adjoining sculpture park. NordArt celebrates its 25th anniversary this year.

The family-owned company ACO was founded in 1946 by Josef-Severin Ahlmann on the site of the Carlshütte steel foundry and iron mill, the first industrial company in Schleswig-Holstein. In the 1980s, his nephew Hans-Julius Ahlmann took the helm and drove internationalization and diversification of the company forward, thanks to which the company is today well able to cushion the impact of regional and cyclical market fluctuations. The next generation, namely his son Iver Ahlmann, managing partner since 2012, is already waiting in the wings. PLM is intended to shorten throughput times In recent years, ACO has grown not only organically but also through acquisitions and today has 41 production sites in 20 countries, in addition to other sales locations. Product development is also distributed across multiple locations and sister companies, some of which use different CAD and PLM systems. "Standardization and harmonization are the cornerstones of our digitalization strategy," says Neff. "A key component in the context of digitalization is implementation of the new PLM system. We expect this to significantly reduce throughput times and improve the quality of the results." ACO's strategy has always involved having a global PLM system – but without forcing the different sites to use it. "Convince, don't force" is our motto, says Markus Matz, who headed up the PLM migration project. The catalyst for redesigning the existing PLM architecture was the desire to connect the Czech sites to Teamcenter. More than 50 design engineers work there with AutoCAD and Autodesk Inventor. Prior to PLM migration, they managed their product data using Autodesk Vault, which made it difficult to exchange data and collaborate with other subsidiaries. ACO maintains a large competence center in the Czech Republic for the development and manufacture of stainless steel products and components, some of which are installed in the products manufactured or distributed by other ACO subsidiaries. The Czech engineers also develop custom solutions, which means that the requirements that the processes have to meet are different to those for developing standard products. It was not possible to map these requirements using the old Teamcenter installation, which had a relatively simple structure. Need for a new PLM architecture Over the years, the divisions that were already using Teamcenter had also accumulated additional requirements that spoke in favor of a redesign of the PLM architecture. The question of switching to a different system did not arise, says Matz: "We were aware of the fact that it was not the system's fault that certain things were not working the way we wanted but rather the fact that we first had to harmonize our process landscape.

That is why we examined all the processes from the original ideas through to the phasing out the products and determined where and how Teamcenter should provide us with support. If possible, we want to document the entire product development process in the PLM system. The different locations, however, have the freedom to use only certain functions." ACO's objective is to create a globally standardized PLM environment without harmonizing the heterogeneous CAD landscapes in their entirety. However, the variety of systems has been reduced to the three CAD systems Autodesk AutoCAD, Inventor and SolidWorks, and Teamcenter has been upgraded to such an extent that data from all three systems can be managed on equal terms. "We are now faced with the task of organizing the handling of multi-CAD data in such a way that data that is generated in one system and used in another is not created twice," says Jochen Bardonner, who was responsible for data migration within the framework of the PLM migration project. One possible approach would be to use the neutral JT format. With the exception of the classification structure, the PLM data model was completely revamped to provide support not only for the development of standard products but also other processes like toolmaking and developing custom products, as well as quality management. "We wouldn't have been able to define different objects and assign different processes to the designs in the old Teamcenter environment," says Bardonner. This meant that the PLM migration not only involved transferring the CAD and PLM data from Autodesk Vault to the new environment but also the old Teamcenter data. Data migration as a core requirement Data migration was a core requirement of the migration project, the setup of which ACO had designed with the help of an external consultant. Not migrating the data or only migrating some of the data was not an option in view of the fact that users in Germany had spent eight years manually transferring drawings from an old drawing management system to Teamcenter. "Data migration therefore played an extremely critical role when it came to acceptance and not just with regard to the Czech sites," says Matz. "The only difficulty was that, when the project was launched, we didn't yet have a data model that would allow us to conduct an informed discussion about the conditions of the migration with a partner." The migration project's setup provided for an agile approach involving eight sprints of four weeks each, adds Bardonner. After approximately four sprints, the new data model had reached a level of maturity that allowed the search for a migration partner to begin. The consultant had recommended commissioning a specialist to perform the data migration. ACO took a look at a handful of suppliers, most of which were quickly disqualified.

The Autodesk Vault/Teamcenter migration was a particularly difficult hurdle to overcome. PROSTEP's impressed first and foremost with its experience migrating data in heterogeneous system landscapes. "The experts PROSTEP got right to the point and asked us the critical questions that were important to us and were very open about what was possible and what was not. This immediately provided us with a structure that we felt comfortable with," says Matz. And Bardonner adds: "We also liked the fact that PROSTEP immediately embraced our project thinking and incorporated itself in the agile process model. That was impressive." Difficult linking of the CAD files PROSTEP played the role of general contractor in the project and brought another partner, who was very familiar, with the data structures of Siemens' PLM system on board for the Teamcenter-to-Teamcenter migration. This meant that the partner was able to break down the objects in the old data model in such a way that they could be mapped correctly to the new data model together with the internal links. Thanks to the seamless communication between PROSTEP’s partner and the Teamcenter experts at ACO, who are based in India, the migration went very well, says Bardonner in praise. In just two days, 3.5 terabytes of Teamcenter data with two million objects were migrated without error. The experts from PROSTEP took care of migrating the CAD and PLM data from Autodesk Vault themselves, a task that constituted a bigger challenge. They used PROSTEP's time-tested PLM migration platform OpenPDM, which has connectors to both PLM systems, to map the PLM data model to the new Teamcenter structure. Correctly linking the CAD files to the new Teamcenter structure, a process that PROSTEP also automated via OpenPDM, was more complex than mapping the data structures. The problem here was that the Inventor interface from Siemens was not designed to handle the mass import of CAD data and often aborted the import operation. To compensate for this shortcoming, PROSTEP had to divide the import operation into smaller "pieces" and at the same time use the logic stored in OpenPDM to ensure that standard and catalog parts that are used in multiple places are migrated only once. "That was not accomplished entirely without error," says Bardonner.

In addition to the approximately 50,000 AutoCAD drawings, a total of 40,000 assemblies, components and drawings were imported from Autodesk Inventor into Teamcenter. In the end, the number of duplicates was around 400. There were also a variety of assemblies that were missing components. These errors are currently being corrected manually. "Overall, PROSTEP managed the technical migration extremely well," says Bardonner. "Our Czech colleagues say that they were able to work with their data immediately after the switch to Teamcenter." Faster processing of customer orders There were, of course, many questions that needed answering in the first few months following PLM migration, as a large group of users suddenly had to work with a PLM system that was new to them. But overall the PLM migration went quite smoothly, thanks to a good training concept that involves key users being trained centrally and then passing on their knowledge to the users on site, says Bardonner. It should also be noted that the new PLM solution is technically much more complex, adds Matz. "But we've done a good job of hiding this complexity from the users." The successful data migration has not only improved data quality but has also contributed to the new Teamcenter solution being more readily accepted by users. It is used more widely than the old solution, no longer just in engineering but also in sales and quality assurance, for example, says Matz. "The fact that – with a few exceptions – all the users can see all the information ensures greater transparency throughout the entire product development process." This transparency has a particularly positive impact on collaboration across different locations and national borders, says Neff in conclusion. "It makes us significantly faster when handling customer projects."

|

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |