|

Making artificial intelligence available for use in PLM processesBy Karsten Theis Artificial intelligence (AI) is constantly conquering new aspects of life. We often use it, knowingly or unknowingly, in our day-to-day lives. AI-based algorithms evaluate our search queries on the Internet, recommend certain products, control the assistance systems in our cars or the household appliances in our smart homes, and much more. AI has also long since found its way into our business world. Industry 4.0 and the digital factory would be impossible without it. We are therefore also working intensively in customer and research projects on how we can use it to optimize product development, and we are developing our first AI-based applications.

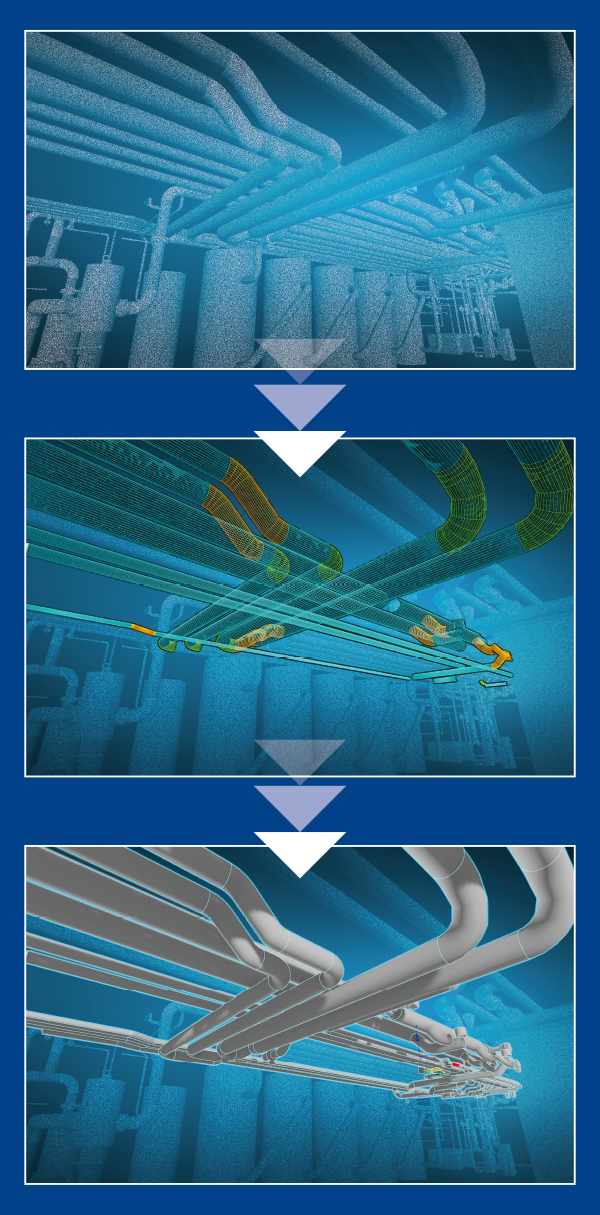

Today, approximately two-thirds of a company's knowledge can be found in the heads of its employees or is distributed across local hard drives and various data silos. This knowledge is essential for product development and manufacturing, and ultimately for the entire lifecycle of the product right through to its disposal. AI is a crucial tool for unearthing this hidden treasure trove of knowledge and linking it to the structured information in the PDM/PLM systems. And it can do this much faster than would be possible manually. AI also makes it possible for conventional PDM, which is only tolerant of errors to an very limited extent, to handle data that is incorrect or incomplete. Nowadays, "weak AI" is typically used to solve specific problems in the PLM context. Strong AI systems that can perform deductive reasoning and thus open up new solution spaces are still in their infancy. The use of weak AI is intended to simplify and optimize existing product development processes that include a high proportion of repetitive tasks and collect data from a large number of heterogeneous sources. The system also learns to make conjectures about future states of the respective process. This makes it possible to parallelize large numbers of process steps that are currently executed sequentially and thus significantly reduce process throughput times. To do this, AI must learn to make appropriate suggestions and realistic predictions based on heterogeneous, decentralized information. A good example is BOM management. As things stand today, BOMs in the automotive industry are usually created by manually enriching and updating previous BOMs based on scattered, barely homogenized information. However, in light of the ever-shorter innovation cycles and the increasing level of variance in vehicle classes, this approach is difficult. But above all, it makes disruptive developments such as electric cars or autonomous vehicles particularly challenging. That is why we developed a concept for partially automating this BOM initialization with AI for a major OEM. This means that the algorithms have to learn to recognize similarities between a new vehicle and the previous models, or even recognize that fact that it is something disruptively new. One of the hurdles in this type of AI project is often collecting a sufficient amount of data for training the neural networks. This is also the problem facing the consortium partners of the ImPaKT research project, which is funded by the German Ministry of Education and Research and headed up by the Heinz Nixdorf Institute at the University of Paderborn. The aim of the project is to make it possible to analyze the technical and financial impact of changes more reliably through the use of an MBSE-based (model-based systems engineering) solution approach with AI support. Among other things, AI is used to evaluate text-based requirements documents and derive structured requirements from them. As part of the project, PROSTEP is developing a software module that will predict the impact of changes. In addition to machine learning, which requires large amounts of training data, there is a second approach to AI that is based on ontologies. Ontologies are used to prepare existing knowledge using formal definitions of terms and their relationships to make it machine readable. They can provide the basis for identifying new correlations using AI. That is why we are also active in this area. Working together with the sports car division of a large automotive group, we are developing an ontology-based approach to data correlation that describes the information located in a large number of IT systems and their relationships using a generic, machine-readable terminology so that they can be linked more easily and across different domains. Many AI-based approaches and applications are still in the development stage. The use case with the greatest relevance in practice is without a doubt image and model recognition using machine or deep learning. We use these methods in our 3DigitalTwin solution to semi-automatically transform 3D scans of existing plants into intelligent 3D models or digital twins. This is a prerequisite for operating the plants more efficiently but, first and foremost, for being able to plan changes to their layout faster.

In other words, we use AI to segment the point clouds of the scanned plants semantically using a two-stage approach. In the first stage, we identify objects such as building structure, equipment and pipings, and then in the second stage, we break down the recognized piping systems into their component parts. Because it is known which point sets belong to which object, which objects (pipe sections, elbows, T-pieces, etc.) are involved and where they are located in space means that the appropriate components can be pulled from the corresponding pipe class and placed correctly in the CAD system. A subsequent topological comparison allows additional information from the associated P&ID of the plant to be linked to the 3D models. Today, plant operators have to invest an enormous amount of time and effort in consistently mapping their plants, which are subject to constant change over the course of their lives, in the digital world. AI speeds up process considerably and makes it more cost-effective, thus enabling plants to operate more efficiently and respond faster to new market demands or regulatory requirements.

You can find out more about our 3DigitalTwin service on our homepage. Take a look and see for yourself. Best regards |

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |