|

IMS optimizes mechatronic product developmentBy Peter Wittkop IMS is the world's leading manufacturer of X-ray, isotopic and optical measuring systems for steel, non-ferrous metal and aluminum production. The company has implemented a mechatronic development process and automated engineering to a greater extent in order to handle customer-specific development projects more efficiently. PROSTEP provided IMS with advice during implementation.

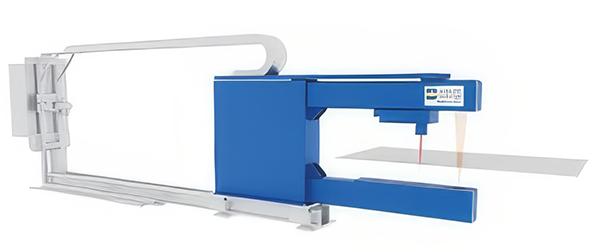

Switching to a new PLM system environment is no easy task for a medium-sized company with limited IT resources, especially when the processes are being revamped at the same time. Good change management is needed if resistance to change is to be overcome. At one point in the transformation process, IMS Messsysteme GmbH was faced with the question of whether it was still on the right track and decided to bring PROSTEP on board. Working together with the PLM consultants from PROSTEP, IMS developed a roadmap for systematic migration to the new system environment. IMS manufactures high-precision measuring systems that are used for quality assurance in hot and cold rolling mills and in the production of heavy plates, long products and tubes. They measure, for example, the width, thickness, length and temperature of the material, inspect the surface quality and detect material defects, which can then be eliminated later during further processing of the coils. Over 4,500 measuring systems from IMS are installed worldwide in production systems for steel, non-ferrous metal and aluminum production. All of the 20 largest international steel and aluminum producers rely on the products from the medium-sized company from Heiligenhaus, Germany. IMS was founded in 1980 and currently employs approximately 460 people in the group of companies, which also includes IMS Röntgensysteme GmbH. With revenues of over 100 million euros, the company is the global market leader generating. What sets IMS apart is, on the one hand, the wide variety of precisely coordinated and customizable systems and, on the other hand, the outstanding worldwide service, as Frank Müller, Head of Mechatronic Design, points out. Which is why the company maintains independent agencies and its own branch offices in 27 countries around the world. New mechatronic approach IMS decided to put mechatronics development on a completely new footing with the aim of avoiding these kinds of errors and improving project management. To this end, the company introduced Creo and EPLAN as new CAx systems, implemented Windchill as an overarching PLM system and set up new processes. In the absence of corresponding functions in Windchill, a team of highly-skilled developers created additional software for synchronizing the mechatronic components in the BOMs. This so-called PLM Manager also makes it possible to configure certain system types automatically.

The measuring systems from IMS are customer-specific developments as they are usually installed in existing rolling mills and therefore have to be adapted to accommodate structural conditions and other constraints. However, IMS had already started to modularize the systems in the old environment, even though configuration still took place in the heads of the design engineers. During the course of the switch to a new system, their logic was compiled in numerous workshops and mapped as a set of rules in the software. This means that both the circuit diagrams and the MCAD models of the measuring systems can be generated automatically. Automation of CAx design In total, IMS has mapped 40 percent of the system types in the configurator, which in turn account for around 60 percent of orders. The others are still being developed using the old CAx systems. The need to maintain two different system environments over a longer period of time was one of the reasons why IMS wanted the route they were taking to be reviewed by PROSTEP's independent consultants. All the more so in light of the fact that the switch to a function-oriented mechatronic BOM means that the employees in Work Preparation have to transform the mechatronic BOM into an MRP or assembly-oriented BOM after transferring it to the ERP system APplus. As Müller says, training employees and helping them adapt to the new mechatronic approach was one of the biggest challenges. "We've trained all the people in Engineering so that they can work with the new systems, but they still have to navigate their way around the old environment," says Müller. And this doesn't just apply to Engineering because the topic PLM concerns the entire company. Work Preparation receives different BOMs, Dispatch receives different delivery slips and Service receives different documents. External manufacturing partners also have to learn how to deal with different product information.

Faster switch to the new system environment In concrete terms, PROSTEP outlined multiple scenarios for the switch, the first of which corresponds to the initial situation and the fourth to a fully mechatronic approach with order configuration and CAD automation, which however is not being planned in this form as it would be too costly. In scenario two, the electrical and mechanical design engineering departments work in a uniform system environment comprising Creo, EPLAN and Windchill but using the conventional and the mechatronic approaches; the latter is supported by the PLM Manager. In the third scenario, the approaches are then standardized, but without automatically generating the CAx documents for all the measuring systems. The consultants came to the conclusion that IMS is well positioned for the future with its mechatronic approach and function-oriented BOMs, and that the transformation of the BOMs in Work Preparation also corresponds to the state of the art found in companies with highly automated processes. The did, however, recommend that the software for BOM synchronization and order configuration developed in-house should no longer be expanded to include new functions. One of the reasons being the fact that the person who created the software has since left the company. Persuasive presentation of the results

It is intended that the switch to the new system environment be completed next year. By then, the CAD models and circuit diagrams from HiCAD and RUPLAN will also have to be migrated in such a way that they can continue to be used in Creo and EPLAN to modernize existing systems. The measuring systems from IMS are characterized by the fact that they are extremely robust and have a long service life of up to 20 years. "We have not yet developed a strategy for the migration, but in PROSTEP we have an experienced partner with whom we can implement this together," says Müller in conclusion. |

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |