|

PROSTEP white paper on digitalization in shipbuildingBy Matthias Grau European shipbuilders began the process of digitalizing their business processes earlier than their competitors in the Far East, but the lead they have built up is shrinking. They must therefore launch a new digitalization offensive that firmly places the digital product model front and center. A new white paper from PROSTEP pinpoints what exactly their digitalization efforts should be focusing on.

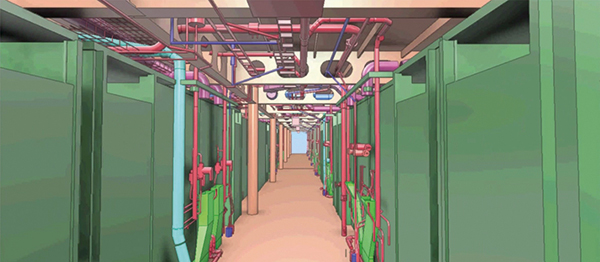

The objective of digitalization in shipbuilding is to develop an end-to-end digital product model that reflects the exact construction status of a vessel across all the phases of its lifecycle. This digital master, which is subsequently used to create a digital twin of the delivered product, not only aids optimization of existing business processes but, in conjunction with data gathered during operation, also makes it possible to develop new value-added services and service-oriented business models. European shipyards, their suppliers and partners need to digitalize their business processes more systematically. There are still gaps in the flows of digital information – especially at the interface between development and production, but also in the exchange of data with partners and suppliers and during the transfer of vessel-related documentation to the owner or operator. A particular challenge here is the exchange of data between mechanical CAD systems and specialized shipbuilding applications like AVEVA Marine, CADMATIC or NAPA because these intent-driven systems do not store the explicit geometry but instead only record the way in which it was created. Such diverging system philosophies hinder not only the horizontal exchange of data between the different CAD systems and downstream applications, e.g. for production control applications, but also the vertical integration with enterprise-wide PDM and ERP applications. The latter is a prerequisite for the consistent management of files, transparent documentation of changes and for establishing relationships to other information objects in the digital ship model. Strategies for a digitalization offensive What should European shipbuilders focus their digitalization efforts on in order to quickly reap the benefits? In PROSTEP's experience, the long-term success of any digitalization push is based on three main points: firstly, the creation of a digital platform; secondly, ensuring end-to-end digitalization; and thirdly, the digitalization of business processes. Integration of the various IT systems creates the foundation for the efficient flow of information and the continuous synchronization of information. PROSTEP has therefore developed a data hub to which all leading CAD and PDM/PLM systems and many of the relevant shipbuilding systems can be very quickly connected. The standard solution not only makes it possible to manage data relevant to shipbuilding using leading PDM/PLM systems such as 3DEXPERIENCE, ARAS and Teamcenter but also to transfer models from mechanical CAD systems to intent-driven ones and vice versa.

The creation of a digital platform does not automatically lead to the end-to-end use of digital information objects. For this to happen, it is also necessary to determine which information objects are required at which point by which process, who will deliver them, and where transfers are currently hindered by format discontinuities. Similar to value stream analysis, PROSTEP uses a standardized method to evaluate information flows and identify redundancies, bottlenecks and disruptions. The results of the analysis can be used to directly define any necessary improvement measures. Solutions for digitalizing business processes can be developed and implemented on the basis of the results of the information flow analysis. PROSTEP has developed solutions for processes such as drawing-free production, 3D assembly planning and creating electronic spare parts catalogs that are suitable for shipbuilding. Initial steps are also being taken for digitalizing vessel classification (class approval), another paper-based process, using 3D PDF technology. From the digital ship model to the digital twin Both the classification societies and the operators have a growing interest in the provision of digital ship data so that this data can be further processed and enriched with their own information. Steps must of course be taken to ensure that the intellectual property of the shipyards is not put at risk. PROSTEP has the know-how and technology required to transfer only the information that the operator actually needs and to protect it using suitable security mechanisms.

The digital models of the delivered ships provide the basis for building digital twins. Their use offers advantages to all the stakeholders involved in the development, construction, operation and use of ships, provided they are willing to share information. Digital twins

Shipbuilders, shipping companies and classification societies will therefore need to agree on a joint approach to tackling the challenges presented by digitalization so that all parties will benefit. The technical solutions needed for this are already available today. PROSTEP can provide marine companies with professional support for their digitalization strategies and implementation of the necessary measures. The PLM consulting and software firm is a recognized partner to the marine industry and customers include high-profile companies such as DNV GL, Lürssen, MEYER GROUP, and thyssenkrupp Marine Systems (tk MS). |

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRESSUM | DATENSCHUTZERKLÄRUNG | HIER KÖNNEN SIE DEN NEWSLETTER ABBESTELLEN. |