|

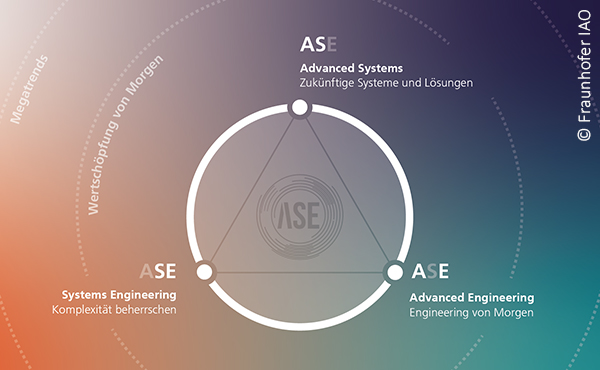

Harmonizing product, process and serviceAn Interview with Prof. Dr.-Ing. Oliver Riedel It is necessary to take a holistic view of the development, production and operation of complex product-service systems. The Fraunhofer IAO is developing technologies and methods to do this as part of the strategic research program Advanced Systems Engineering (ASE). The director of the institute, Professor Oliver Riedel, describes the scope of the approach and the challenges posed by implementation. Question: Professor Riedel, what is meant by advanced systems engineering and what makes it different from systems engineering? Riedel: In the past we haven’t been able to establish systems engineering in such a way as to deliver really good solutions for the combination of product, process and service. Systems engineering works reasonably well for mechatronics and software engineering but often fails in industrial practice because of the complexity of the approach and the organizational structures it requires. Advanced systems engineering (ASE) is designed to address precisely these issues and to better support companies when it comes to implementation. Question: Does the term ‘advanced’ refer to systems or to engineering? Riedel: It can be understood as a triangle that brings together the three aspects of advanced systems, systems engineering and advanced engineering. Advanced systems describe increasingly complex and networked market services, systems engineering describes the coordination and structuring of the cross-functional, interdisciplinary development of complex systems, and advanced engineering deals with best practices with regard to methods and tools in engineering, as well as agile approaches and creativity techniques. The aim is to break down domain silos and enable interactive collaboration in both product engineering and production, in other words to achieve a holistic view of the innovation processes. Question: Are you placing the primary emphasis with ASE on dovetailing product development with production and production planning? Riedel: Not quite, we are going even further. After all, products and processes are still largely developed in-house. In the case of product-service systems, the service is provided after the start of production, when the product is already on the market. And things that change the product without any physical add-ons, such as big data analytics or product updates over the air, play a role here. The system must be described as a coherent whole, in order to be able to use it in product development, virtual try-out, the digital factory and, most importantly, in the field of service.

Question: And what does that mean in concrete terms? Riedel: Let’s take Homag and its highly complex custom systems for the woodworking industry as an example. The company has adopted an ASE approach, in order to achieve one hundred percent mapping of the digital twin. However, this twin does not reside in the development department but instead accompanies production virtually. If the owner of the machine wants to use the machine to run a new production program, they can try it out virtually on their system. The digital twin is used as a service during operation. Question: Implementing systems engineering in development is already a complex task. Are you not merely compounding the complexity by integrating production and service? Riedel: Of course, the notion of service is an additional dimension but that doesn’t necessarily make things more complicated; it simply brings together those processes that are still segregated today. There must be a single source of truth for the entire system. In other words, the system model must be linked with the service structures when the system is really running. Nowadays, we don’t get the data back from the field so that we can map it to the product and offer additional services. But the product lifecycle doesn’t come to an end when the product is delivered. We need redundancy-free storage of data throughout the entire lifecycle, despite the user having a different view of this data from that of a developer. Question: In principle, ASE requires that everything should be defined from the outset. Doesn’t that clash with the philosophy of the agile approach? Riedel: No, I don’t think so. In the model-based approach we have for simulation technology what is known as black boxing. I can create certain components as black boxes with inputs and outputs without having defined them in full detail, either because I don’t yet know the solution or because I’m not interested in it at present. I don’t need to know the internal workings of each black box from the word go. I just know that it has to be there. If you apply this paradigm broadly, you easily get to agility. The only question is whether there are enough description languages that can cope with the various modeling depths in the simulation. Question: Is ASE model-based by definition or are there other approaches? Riedel: I’ll answer that with another question: Is there anywhere you can still do without models today? Yes, it definitely has to be model-based, because we would otherwise be unable to achieve coverage of all the phases or the required depth. Question: What models are required for this? If you want to dovetail product, process and service, surely you have to start with the requirements? Riedel: Exactly, this is one of the issues that is the subject of intense discussion. Can we achieve this with one data model across the entire lifecycle or do we link models? From my practical experience in industry, I would prefer linked models because a single model would eventually become too much for me. Not only that, I’m also no longer interested in the fine details of the requirements model after a given phase. In order to go into production, I need other models, but it must be possible to link them to each other, in much the same way as the different views in PDM. And when I go out into the field, it is again the case that I no longer need certain details. But I must be able to establish relations in both directions. In other words, I am linking my models but the content doesn’t have to be a permanent part of every version of the model. Question: Can ASE work in conjunction with external suppliers? Don’t you reveal too much product know-how if all the information is contained in a single model? Riedel: That’s a very good point, and it brings us to the operational use of such models. Until now, we’ve only talked in the abstract about what they might look like in a perfect world. The management of roles and permissions, which is already a hot topic in the distributed development process, becomes an even greater challenge when the network is extended to cover the users of the product as well.

I clearly don’t want users to see everything, but just the relevant information and structures. Ensuring the management of roles and permissions beyond the current system boundaries is a truly intriguing issue. Question: Are there any companies that have already implemented ASE right through to service provision? Riedel: Unfortunately, there are very few due to the fact that there are three major hurdles to overcome. Firstly, there are technical hurdles such as model-based description languages, but these will be overcome at some point. Then there are organizational hurdles within companies. Perhaps these will begin to fall away a little as a result of the coronavirus, because many people realize that we would be much further down the road if we already had connectivity across domains. Companies are not yet organizationally geared up to plan and control product lifecycle support. And then there are the human hurdles. To start with, you have to get engineers onboard in your journey into the next dimension and get them to understand the growing complexity that comes with it. At the moment, I think that the organizational and human hurdles are greater than the technical ones. Question: What is the focus of the ASE research program at Fraunhofer IAO? Riedel: We have decided on six areas of study, which we work on in two directions. The first of these areas is model-based system development, including cross-domain aspects such as data analysis, in other words, the extension of current methods. The second is value-stream-oriented product design, i.e. the use of process information from production for product design. For this to succeed, the value stream must be defined at an earlier stage than it is currently. The third area is the evaluation of data from production planning and production using artificial intelligence (AI). And the fourth area also has to do with AI, but in this case, it is about evaluating the large volumes of data from the product engineering process in order to provide product developers with recommendations for best practice. The fifth area deals with system configuration, i.e. how to configure not only the product but also the process and the service, for example in order to be able to assess the impact that changes made to the product may have on the process. The last area we are investigating may be somewhat old-fashioned, but we must have another look at the PLM systems. They are still not in a position to support ASE. Question: Where, for example, should the product-specific process information be managed? This issue is actually more closely related to MES. Riedel: We undoubtedly need MES functionality to be integrated into PLM, either via interfaces or by running it on the PLM infrastructure. Assuming that MES and PLM systems were to evolve towards service-oriented architectures, the existence of x different systems wouldn’t be tragic because they would be based on a data repository, and this would ensure that the models were linked and would guarantee their consistency and integrity. However, this runs quite counter to the architectural pattern of today’s PLM systems. Question: A moment ago, you spoke of ‘two different directions’. What did you mean by that? Riedel: We have had long discussions with the Ministry of Economic Affairs of the State of Baden-Württemberg, Germany, about how we can ensure that the issues are quickly made tangible for local companies. So we set up a mobile lab in which we are using a relatively simple product with a service feature and a production system that can be quickly understood to illustrate the interaction of engineering, production processes and service. The lab is housed in a shipping container, which is currently standing on our premises due to the restrictions resulting from the coronavirus pandemic. The other direction is to build a similar lab at the Fraunhofer IAO, but this one is oriented more towards research. Question: What insights can companies expect from this plug-in lab? Riedel: To start with, they can quickly grasp exactly what is meant by model-based system development or value-stream-oriented product design. The idea is that they can feed their own data into the lab equipment and directly identify the added value. We want to use a simple example to demonstrate to companies how ASE works. Professor Riedel, thank you very much for talking to us.

Professor Oliver Riedel (born 1965) has been head of the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) at the University of Stuttgart since November 2016 and is also a director of the Fraunhofer Institute for Industrial Engineering (IAO). Professor Riedel studied Cybernetic Technology at Stuttgart Technical University, where he completed his doctorate at the Faculty of Engineering Design and Production Engineering. He has been working on the principles and practical application of virtual validation in product development and production for over 25 years. Professor Riedel is married with one grown-up son. Further information is available at www.iao.fraunhofer.de |

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |