|

DART Racing Team brings racing season to a successful closeBy Joachim Christ The DART Racing Team at the Technical University of Darmstadt, which is sponsored by PROSTEP, has successfully completed this year's racing series. The team took part in the three Formula Student competitions, held in Italy, the Czech Republic and Germany, with its much improved pi2023 electric racing car. Its best finish was 2nd place at FS Czech 2023, which was held at the Autodrom Most race track.

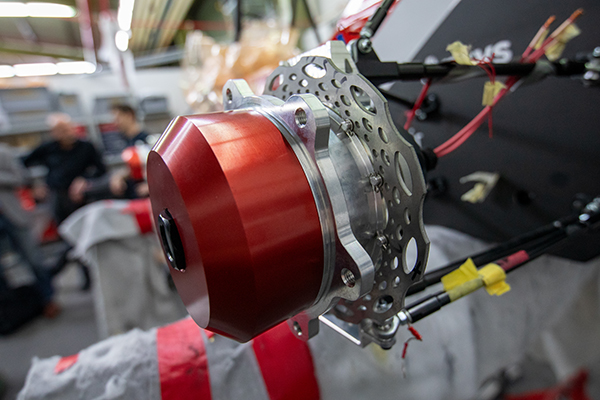

Formula Student (FS) is an international university design competition in which students from all over the world compete with racing cars that they have designed and built themselves. It is not the team with the fastest car that wins but the one with the best overall concept. At the FS competitions, the judges also evaluate the innovativeness of the concept and aspects such as cost planning. The TU Darmstadt Racing Team e.V. (DART) has been taking part in FS competitions since 2006, initially with a race car powered by a combustion engine and, from 2011 on, with an electric racing car. In 2017, it also started competing in the Driverless class. In the past, the car from the previous season was always converted for this purpose. In the 2020/21 season, the students developed a hybrid vehicle that can be used in both classes for the first time. The pi2023 takes this concept a step further. Completely self-developed Although the pi2023 builds on its predecessor and the experience gained during the course of the previous year, it is a completely new vehicle. Unlike other teams, the DART Racing Team is in a position to build a new car every year and does not need to make use of components from the previous year. With the exception of purchased parts, the vehicles have to developed in their entirety by the teams themselves. The students use different software tools to do this – the CAD system Siemens NX, the electrical engineering software E-Plan, the software Ansys for finite element calculations, the simulation software IPG CarMaker, the driving simulator VI-grade, etc. The virtual vehicle is managed with the software SVN, which is actually a tool for version control during software development but which can also be used for the CAD assemblies. A Confluence environment with different workspaces was created in order to make know-how available to other team members and subsequent generations of students. When it comes to manufacturing, the DART Racing Team can call on the help of external partners, who take on the more complex tasks, such as turning and milling or even 3D metal printing, as a form of sponsorship. "Everything that we can do by hand, such as model making, laminating the carbon fibers and assembly, we do ourselves," says Schwerdtfeger. The team has a workshop in Pfungstadt for this purpose. Electric motor developed by the team Compared to its predecessor, which was the first to be equipped with a hub motor developed by the team, the new racing car contains numerous innovations and further developments. Schwerdtfeger explains that, unlike the purchased electric motors used in the past, the electric motor that the team developed itself has been specifically designed to fulfill racing-related requirements. This applies in particular to the option of distributing torque to the four wheels in a flexible manner. However, the motors were not able to bring their full performance to the road last year due to problems with heat dissipation. Which is why both the arrangement of the cooling ducts in the 3D printed metal housing and the design of the entire cooling system were optimized in the pi2023.

Schwerdtfeger also used multibody simulation software to optimize the undercarriage kinematics. The new arrangement of the wishbones changes the alignment and camber of the tires. This reduces the steering forces required, which has a positive impact on vehicle dynamics, especially when curve driving quickly in autonomous mode. However, as Schwerdtfeger explains, the new arrangement of the wishbones required changes to the attachment points on the monocoque. The team has also made changes to the chassis that are barely visible at first glance. The different structure of the carbon layers has reduced the weight of the monocoque by almost another five kilos to just over 30 kilos. The team has also redesigned the front wings based on flow analyses in the wind tunnel and optimized the side boxes to further improve aerodynamics and wheel grip. Competitive advantage when it comes to software The software used for autonomous racing also includes key new features. The vehicles previously used a LIDAR laser sensor, which generates a 3D point cloud of its surroundings, and two cameras, which were able to detect curves based on the color of the cones, to guide them around the course. As Schwerdtfeger explains, "We've now made it possible for the software to recognize right turns and left turns without using cameras, and we've optimized the course so that the vehicle doesn't always drive in the middle." That represents a significant competitive advantage at driverless competitions. All these innovations and improvements not only have an impact on the race but are also included in the evaluation of the teams. In the FS competitions, it is not only the dynamic disciplines, such as acceleration, cornering, the fastest lap on the actual track and the endurance race over 22 kilometers, that count. The judges also evaluate how the teams have implemented certain things and look for flaws in the design, while the teams try to direct the judges attention to where they can impress. "It's like a game of cat and mouse," says Schwerdtfeger.

Participation in three FS competitions This year, the DART Racing Team participated in three European competitions. Unlike Formula 1 racing, qualifying for the competitions does not take place on the race track, as the cars are not yet ready, but as the result of a series of quizzes. Teams spend a day solving fairly difficult engineering and computer science problems and answering tricky physics questions for each race in which they want to participate. The FS Germany in Hockenheim, with its 70 teams, is the most prestigious event in which the DART Racing Team participated this year. "It’s something along the lines of an unofficial FS World Championship," says Schwerdtfeger. Having placed fifth in the Driverless class last year, it did not necessarily need to take part in the qualifying but nevertheless did so in order to gain one of the front spots for the technical inspection of the vehicle and thus have more time for making any modifications that might be needed. Although the students are given quite a bit of freedom when designing the racing car, they have to provide proof of certain aspects, such as braking safety, the durability of the mechanical components, the functional reliability of the autonomous systems and the protection of the electronic components against rain, before each race.

Team comprising different disciplines The DART Racing Team currently comprises approximately 35 students from different disciplines and subject areas, from mechanical engineering to electrical engineering and information technology, mechatronics and computer science through to industrial engineering. Women are clearly in the minority but in some cases assume responsibility for key tasks such as data engineering, i.e. evaluating sensor data from the vehicle in order to, for example, train drivers on the simulator. "The proportion of women is the same as in the field of mechanical engineering in general but we'd like to increase their number," says Schwerdtfeger. Anyone who would like to participate is welcome to apply here. Although participants should be students, they do not necessarily have to be studying in Darmstadt. Finding new recruits is not currently a problem, despite the fact that participation in Formula Student is a time-consuming undertaking. There is not much time left over for studying. Which is also why the composition of the team changes from year to year. "The biggest challenge is quickly bringing new members up to speed," says Schwerdtfeger, who is now in his second year on the team. " But it's also important to have the budget plan in place as early as possible." As Schwerdtfeger points out in concluding: While other teams are funded in part by their universities, the DART Racing Team is financed exclusively by sponsorships. The department managers and the team leader are therefore also responsible for maintaining contact with existing sponsors and acquiring new sponsors. As of this year, PROSTEP is new a Gold Sponsor . Our logo looks good on the racing car's black, white and red monocoque. |

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |