|

Artificial intelligence gives the digital twin a boostA guest article by Bernhard Valnion PROSTEP presented an innovative approach to the automatic conversion of 3D scan data for existing plants into a digital twin at Schuller & Company's DACH User Meeting. This makes both the maintenance and the modernization of the plants easier. The publicist and analyst Dr. Bernhard D. Valnion summarizes the key findings in a guest article. The digital twin is considered one of the key concepts of Industry 4.0. Behind it is a whole conglomerate of promising use cases such as the virtual commissioning of a plant, or parts of a plant, or its use as the basis for planning maintenance and modernization measures, for example. These use cases have what it takes to mutate into business cases, in other words: the benefits gained exceed the expenditures involved. It is agreed that the digital twin offers great potential in the context of factory planning and the construction of large plants in particular. However, the crux of the matter up until now was identifying the objects in the laser scanning point clouds that are appropriate for planning new buildings or other measures. The point clouds needed for this are currently loaded into the CAD systems as "templates" that provide the basis for modeling the piping system manually. This is extremely hardware resource intensive, time consuming and therefore expensive. PROSTEP AG, together with Schuller & Company, is now taking an innovative approach that involves the use of artificial intelligence methods. Johannes Lützenberger from PROSTEP reported on the status of current developments at Schuller & Company's recent DACH User Meeting 2023 at Frankfurt Airport. Plants are constantly changing Put simply, the lifecycle of a plant comprises at least three phases. The starting point is the planning phase (as-designed status). Once the plant has been erected, the planning data no longer corresponds to what has been built on the construction site (as-built status). Then, during the operational phase with all its MRO (maintenance, repair and overhaul) activities, changes are made and adaptations are performed. Not everything is documented digitally. Precise information about the actual situation on the ground should, however, be available at particular points in time, for example because modernization measures are to be performed and thus changes made to the plant. If image recognition software is used, it is important to remember that there is a (significant) difference between 2D image recognition and 3D object recognition within a spatially extended point cloud. In the case of image points, there is a linear relationship between neighboring pixels; in the case of a scan, each point stands alone. Power plant use case In the approach developed by PROSTEP and SCHULLER & Company, the input is also the point cloud. In the first step, the amount of data is reduced in order to make the volume of data manageable. The second step involves recognizing objects in space. This is done in a two-stage process, which makes it possible to get to grips with the complexity of the plant. At this point, no relationships between the individual laser points have yet been identified by the algorithm. This means that it not yet known which points describe which component.

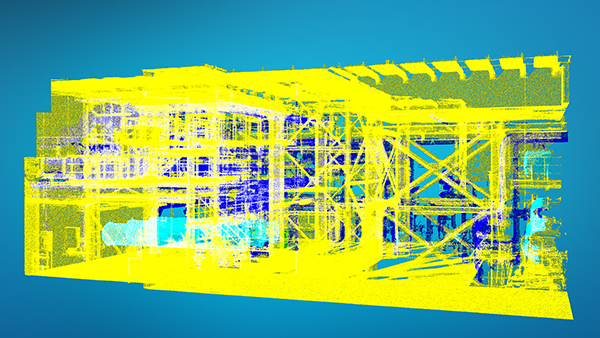

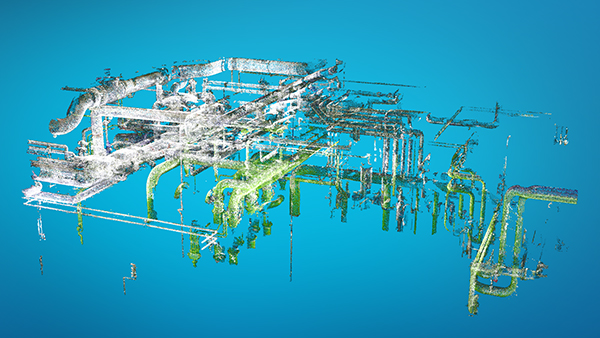

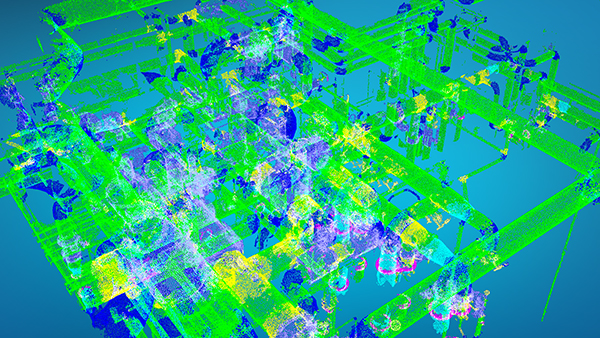

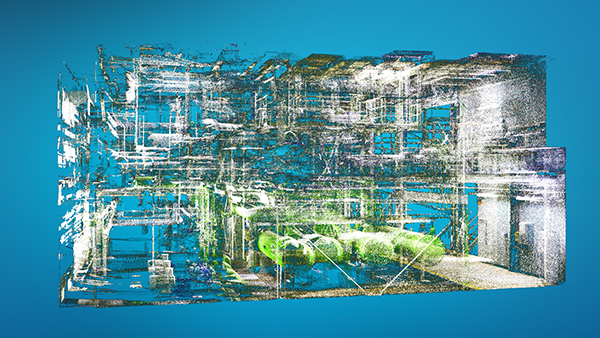

Johannes Lützenberger demonstrated the results of the collaboration between the two companies using the point cloud from a power plant near Hanover as an example. It has a spatial extent of approximately 10 x 20 x 5 meters. Recording the current status resulted in 76 million laser points (2.3 GB). These were reduced to approximately 330,000 points or 100 MB. The reduction factor is thus 95 percent, which is sufficient for further processing. The next step is segmentation, i.e. the detection and isolation of the piping system in the plant. This involves assigning each point a class and storing it. As Johannes Lützenberger explained, no information is lost even if a point is assigned to the wrong class. Points can be stored with colors (see graphics).

Another deep-learning algorithm delves even deeper. The aim now is to identify components of the piping system such as flanges, pipe elbows and T-pieces. Only envelopes are however recognized and not what is in the subcomponents.

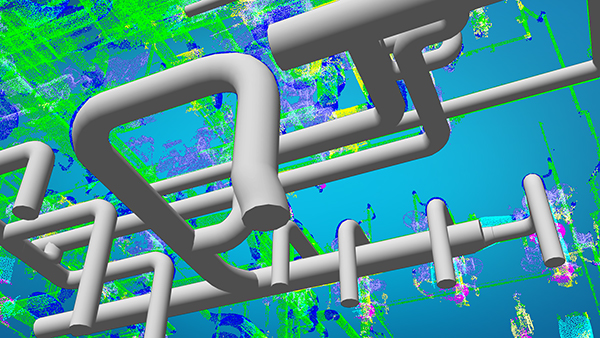

The next step therefore involves what is referred to as clustering. Points are grouped together and geometric information and information about the position in space is derived. The aim is to create a CAD model that can be imported into AVEVA E3D. It describes the current status and provides the basis for replanning.

The next step therefore involves what is referred to as clustering. Points are grouped together and geometric information and information about the position in space is derived. The aim is to create a CAD model that can be imported into AVEVA E3D. It describes the current status and provides the basis for replanning.

Differences in the pipe components must then be resolved and the objects lined up correctly. To do this, the center lines need to be identified. This is done in conjunction with the planning tool AVEVA E3D, which also determines the correlation with the piping and instrumentation diagram (P&ID). It is a semi-automated process that offers great potential. It means that the method can help plan maintenance measures, something that has not been possible up until now for economic reasons. This is appealing in that not only the P&I diagram but also spatial information is then available, which provides for better orientation. This makes it possible to optimize the timing of the planned measure in advance. Johannes Lützenberger concludes that "the beauty of AI is that it keeps on learning. Which means that its performance capabilities are getting better and better." True enough.

About Dr. Bernhard D. Valnion Dr. Bernhard D. Valnion has followed the CAx industry as an editor, analyst and publicist for 25 years. He is CEO, founder and president of d1g1tal AGENDA UG, which among other things publishes the magazine d1g1tal AGENDA quarterly. It also offers the sub brands d1g1tal HUMAN (podcast about movers and shakers in the age of digitalization) and d1g1tal LOOPs (process mining). Dr. Valnion received his doctorate in experimental physics from LMU in Munich, Germany. |

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |