|

OpenDESC.com offers analysis of scan dataBy Josip Stjepandic The digital representation of production plants is a prerequisite for material flow simulations and the analysis of bottlenecks when planning or making changes to the plants. PROSTEP now offers its customers a new service for this purpose: The automated analysis of 3D scan data and conversion of this data into digital twins that can be used to simulate production processes. Up until now, a considerable amount of effort was needed to create digital twins for existing plants, which made their use difficult for small and medium-sized companies in particular. As part of the DigiTwin research project, the Institute of Production Engineering and Machine Tools at the Leibniz University of Hanover, together with PROSTEP, isb - innovative software businesses and Bornemann Gewindetechnik, has developed a service concept for deriving simulation models from scans of the factory floors largely automatically. The project, which is being funded by the "SME innovation: Service research" initiative of the German Federal Ministry of Education and Research, is nearing successful completion.

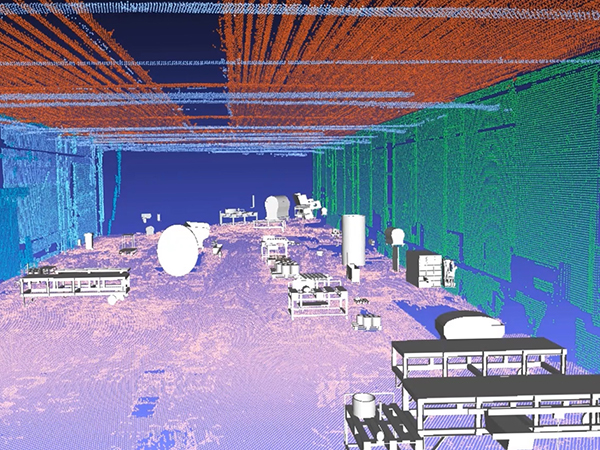

The aim of the research project was to use object recognition to convert, with a maximum of automation, the 3D scan data from production into digital models that can be used to perform simulations. Both standard scanners and stereo image cameras were tested for use as devices for scanning the systems. The experts from PROSTEP's data management team transformed the "dumb" point clouds of machines, robots and transport equipment into "intelligent" CAD models that can then be used to simulate the manufacturing processes. Strictly speaking, the scan data, or the network geometry derived from it, was not converted directly into CAD models, but was first analyzed using artificial intelligence methods and machine learning to identify plant components for which simulation-capable CAD models already exist. Setting up the corresponding library was a key part of the project. Only if there were no equivalent in the library was the scan data converted into CAD models, parameterized using feature recognition methods and prepared for simulation kinematically. The experts from PROSTEP use SolidWorks to develop the CAD models; they can however be output in any CAD system. The objects on the factory floor were divided into seven categories to make classifying them easier. A so-called bounding box for each object was used to accurately determine the position and orientation of the objects in space and to check the results of object recognition. Depending on the category, 80 percent of the objects could be identified automatically and stored with the corresponding CAD models, which dramatically reduced the effort needed to create the digital twins for material flow simulations. The sustainability of the innovative service concept from the DigiTwin project is guaranteed: PROSTEP has now expanded the range of services offered by its OpenDESC.com data transfer and conversion service to include the automated analysis of 3D scan data.

|

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |