|

PLM is a long-distance flightAn interview with Dr. Henrik Weimer Dr. Henrik Weimer, who was recently appointed spokesman of the board of the prostep ivip association, is primarily responsible for the corporate IT architecture for digital design manufacturing and service capabilities at Airbus. In an interview, he explains the challenges facing the aircraft manufacturer in the design of its PLM architectures and where the aerospace industry is headed. Question: Mr. Weimer, you are responsible at Airbus for corporate architecture in Digital Design Manufacturing & Services. Is all this part of PLM?

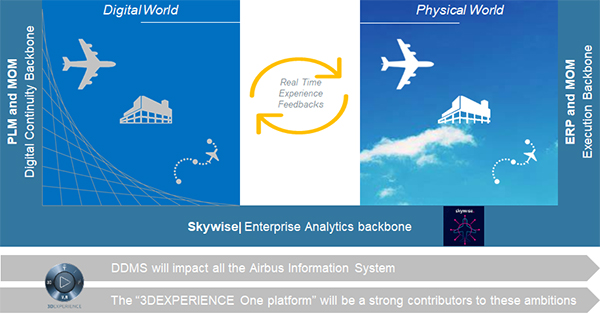

Weimer: We've come a long way to our current understanding of PLM, from product data management to the entirety of the engineering tools we use to support our product development, to the idea of the model-based company. What we call PLM today is really an integrated and model-based approach to design, manufacturing and services. Not only do we describe our products in models, we also have models of our industrial process and the support and service processes. The challenge is to represent the trade-offs across all these disciplines. For example, whenever we make a product change, we need to be able to see how it affects the industrial process and what impact it has on support and service and on my customers - doing this analysis based on models and simulations. Question: How does Corona affect the PLM strategy and ongoing initiatives? Weimer: Of course, the Corona crisis affects aviation particularly strongly. This is a dramatic situation for the industry, which is why the industry is focusing on the essentials. But the crisis is also an opportunity for PLM and digital transformation, as I have said elsewhere, because the decline in activity in certain areas reduces the cost of transformation, creating opportunities, and gives us access to resources that may not have been available to us before. Question: Can the Airbus PLM strategy be described in a few sentences? Weimer: We have an enormous diversity of around 3,000 tools around the PLM, which means we have extreme complexity and extreme integration problems, which results in processes that are not yet particularly consistent. Where we had a best-of-breed approach for every capability in the past, today we think this complexity reduces innovative strength and is not cost-optimal. Therefore, our current vision is to move more towards integrated platforms, which is why we have entered into several partnerships. For example, we partner with Palantir to bring data analytics and the product digital twin together in the Airbus platform Skywise, making it available to our customers as a product. We have also entered into a strategic partnership with Dassault Systèmes. Our vision is to establish 3DEXPERIENCE as the collaboration platform for digital design, manufacturing and services to move towards more integrated, model-based and data-driven processes. Then there are capabilities for various disciplines orchestrated through 3DEXPERIENCE. This can include proprietary or 3rd party capabilities, e.g. for configuration management, which are not efficiently supported by today’s commercial solutions. Question: What does the strategic partnership with Dassault Systèmes mean for the other PLM systems in use at Airbus? Weimer: PLM is a lifelong journey, and over the years there have always been opportunities to work with different partners. For example, Windchill was selected as the PDM platform for the entire Airbus Group at the beginning of 2000 and continues to play an important role. Similarly, we selected Aras more as a niche solution on the PLM periphery to better control creativity in our business. Finally, we develop many process automation tools and solutions internally, e.g. for structural testing, aerodynamics simulation, etc. Question: How many different PLM architectures are there at Airbus? One for each aircraft program? Weimer: That would be too much simplified. Every time we launch a new product program, we have the opportunity to invest in innovation and digital process improvements. We started in the 1980s with the A320 program with integrated product data management, then in the 1990s with the A330 / A340 program, we first introduced the 3D digital mock-up in addition to PDM. Then came the A380 in early 2000, where we worked with the 3D model as the master and integrated processes for configuration management. This was followed by A400M, A350, and other developments that went deeper into the journey to model-based and digitally integrated processes. PLM architectures evolve significantly from one program to another to drive our digital transformation, but there are always elements that are reused to leverage our past investment, and to reduce risk for the next program.

Question: Will the process improvements also be fed back into the running programs? Weimer: We return them to where we can generate added value through the investments. Because the initial investment has already paid for itself on the new program, it is easier to finance retrofits of the capabilities in running programs. In addition, even our legacy aircraft programs still run significant developments, such as the re-engineering in the A320Neo and A330Neo programs, or the current development of the A321XLR, with which we are dramatically changing the range and market positioning. With each new product variant, we have significant development expenses again and can also justify investments in digital transformation and further process improvements. Question: How far have you progressed with the Group-wide harmonization of PLM architectures? Weimer: Airbus was founded in 1969 as a kind of association with an integrated product, but this product was developed by four different companies that had different processes and IT systems. We have been an integrated company since the beginning of the millennium and have also made enormous progress in integrating the system landscapes since then. With programs such as the A400M or the A350, there is only one set of processes, methods and tools that is used at all locations, not only in the founding countries but also in the global engineering centers across the globe. And we have now an aligned strategy also across business units driving through a single group-wide digital design, manufacturing, and services transformation program addressing all business lines and product families. Question: Are the methods of Model-Based Systems Engineering already firmly integrated in the product development process? Weimer: For many years now, we have had approaches towards MBSE in various areas such as powerplant, fuel, noise, electrical or avionics. What we are still working on is to better and more globally integrate this in order to be able to consistently present the trade-offs between the product as a system, the industrial system and the support and service system. To achieve this, cross-disciplinary cooperation in Model Based Systems Engineering must be improved even further. Question: How universally is the Digital Twin used today at Airbus? Weimer: As I said, we offer it as a service via the Skywise platform. Our products have the option of uploading data from operations to the platform, so that we can provide our customers with analytics services for route optimization or maintenance planning optimization, as examples. In addition to the Digital Twin capabilities for our customers, there are also projects in production to calibrate our models and optimally control processes via analytical control procedures. One example is the topic of fasting - there are tens of thousands of fasteners in an aircraft. Using IoT-connected tools, we can prove which elements have been set and with what torque they have been tightened, thus reducing inspection costs. Question: At Airbus you are also responsible for PLM research. Where are the main focuses in this area? Weimer: A good example is the topic of 3D printing. We see an enormous potential for 3D-printed components and have therefore had projects in the recent past to make design optimizations. For this purpose, we have developed new capabilities in our partnership with Dassault Systèmes, in order to optimize the shaping of the parts on the one hand and the printing process on the other.

Question: In which PLM topics do you see the aerospace industry ahead and can perhaps serve as a model for other industries? Weimer: I find it difficult to make a statement on this because it might sound arrogant. My personal conviction is that we have to remain humble and can all still earn from each other. Nevertheless, the aerospace industry certainly has a long history in all topics related to safety and the verifiability of product safety. There are many regulatory requirements where we have to prove very precisely, for example with the help of systems engineering, that our product meets these requirements. And the industry as a whole is deeply collaborating to achieve these safety targets, including the regulators, international governance bodies, etc. Here I see many parallels with autonomous driving in the automotive environment, where there are still no clear regulations and requirements that are internationally standardized. Question: Do these experiences flow into the projects of the prostep ivip association? Weimer: Yes, we have, for example, just started a project on the topic of Model Based Verification and Validation on the initiative of colleagues from The Boeing Company. One of the aims of this project is to use simulation models for such verifications. We want to be able to prove that the simulation correctly represents reality in order to avoid physical test set-ups. Question: Which accents would you like to set as the new spokesman of the association's board? Weimer: We have similar challenges in aerospace, automotive and other industries when it comes to optimizing products and production processes. In my opinion, the association is an excellent platform for collaboration, for learning together and defining best practices, especially in the interaction with our supply chains. The idea of collaboration is a passion that I bring with me. The second topic I want to work on is internationalization, because I believe that innovations around our topics are not tied to a geographical region. Mr. Weimer, thank you very much for the interview.

Dr. Henrik Weimer (1971) has worked in Airbus since 2002 and is currently Senior Manager responsible for the architecture and integration of end-to-end PLM solutions, demand and business planning for PLM, as well as innovation, research and development in these areas. Previously he held various management positions in IT at Daimler AG. Weimer studied computer science and electrical engineering at the Technical University of Kaiserslautern and received his doctorate in computer science from Rice University in Houston. Since 2018 he has been a member of the board of the prostep ivip association, which recently appointed him as its spokesman. |

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |