|

Holistic Method for validating highly-automated driving FunctionsBy Christian Bühler The VVMethods project was brought to a successful close at the end of last year with a conference at the Carl Benz Arena in Stuttgart, which was attended in person by 300 people and over 600 people online. Important contributions made by PROSTEP include SysML-based documentation of the overall method and its implementation in the TRACY demonstrator. This means that it be used as a blueprint for industrial implementation.

Highly automated vehicles must function safely and reliably in every conceivable driving situation. The verification and validation of the driving functions and proof of their safety play a key role in determining how well the new technology will be accepted. The complexity of automated vehicles and the large number and diverse nature of possible traffic scenarios mean that they can no longer be tested on the road without having to invest excessive amounts of time and money. This is why 22 partners in the joint VVMethods project, which was funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK), have developed a holistic method that provides digital proof of safety and integrates verification and validation in the vehicle development process. VVMethods is one of two projects concerning the validation and verification of automated driving functions in which PROSTEP has actively participated; its sister project, SET Level, ended in 2022. Our job in both projects was to provide the project partners with support in the context of defining requirements and implementing the project results in industrial applications. We also developed the demonstrator for a traceability solution, which makes it possible to baseline simulations in heterogeneous IT landscapes, in both projects. After both projects came to an end, we incorporated TRACY in our digital thread solution OpenCLM. In total, over 30 PROSTEP employees were involved in the two projects over a period of more than four and a half years. As Dr. Martin Holland, Head of Strategy & Business Development, points out, "Close collaboration with the other project partners from industry and the research community has made it possible for us to build up expertise in the field of autonomous driving and deepen our knowledge of model-based systems engineering (MBSE) tools and methods enormously. We have also succeeded in raising PROSTEP's visibility as THE expert for end-to-end digitalization."

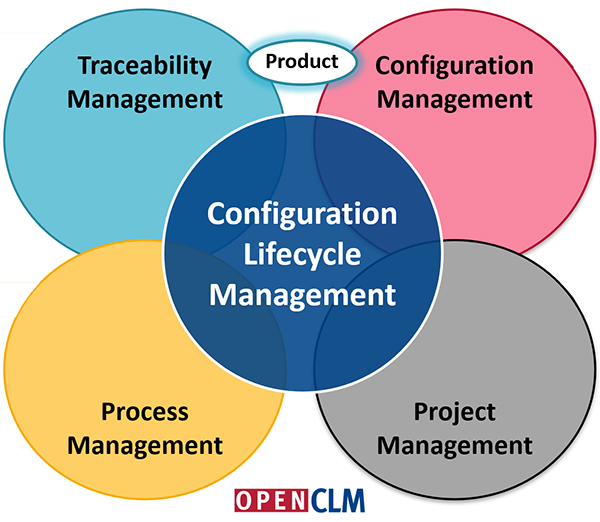

While the sister project, SET Level, focused on defining a reference process for the virtual simulation of automated driving functions, the main objective of VVM was developing methods for providing proof of safety. The project made use of the established scenario-based approach to develop and document test procedures and methods that can be used in industry to validate automated driving functions. Merely developing them is not enough. They also have to be described in a consistent manner that can be readily understood if confidence in these new vehicle functions is to be built and they are to be accepted by society and legislators. The driving functions are subsequently validated using a huge number of synthetically generated scenarios or scenarios from the real world. The project partners designed a holistic method within the framework of the VVM project. It starts with the definition of requirements and security concepts early on in the development process so that key safety aspects can be incorporated from the outset and implemented constructively. The method also takes account of aspects such as risk assessment, scenario creation, customer functions and the roles played by the companies involved (OEM, tier x, etc.) with the aim of developing an easily understood and credible safety-related line of argument. In addition to collecting and bundling requirements, a key task performed by PROSTEP was making the knowledge gained in the project available to the industry partners. We merged the results from the sub-projects, consolidated them and mapped them in a SysML model that guarantees the consistency and traceability of the method. Anyone interested can view this model. The model's formalized description and graphical representation provides easy access to the VVM method and makes it easier to understand the relationships between the process steps or activities and the development artifacts exchanged between them. As was the case with SET Level, the project partners used our demonstrator TRACY to map and document the entire method developed in the project in terms of IT. Implementation of the VVM method makes it possible for users to carry out a wide range of different dependency analyses, on the one hand, and to enrich the abstract methodological components with concrete company-specific development artifacts, on the other. The current implementation in TRACY can therefore be used as a blueprint for industrial application of the method, which supports effective introduction of the VVM methodology in companies. Thanks to its large number of standards-based connectors, it can be implemented in existing system landscapes with little effort. TRACY has become a key component for ensuring the end-to-end digitalization and traceability of development processes in our traceability solution OpenCLM. OpenCLM makes it possible for companies to analyze cross-domain dependencies between the artifacts in different source systems and assess the impact of changes on the artifacts involved. Linking to the source systems makes it easy for users to assess changes across domains and systems. This enables companies to make well-informed decisions. VVMethods and its sister project, SET Level, have therefore made an important contribution to our product development and make it easier for our customers to ensure end-to-end digitalization and traceability.

|

|

| © PROSTEP AG | ALL RIGHTS RESERVED | IMPRINT | PRIVACY STATEMENT | YOU CAN UNSUBSCRIBE TO THE NEWSLETTER HERE. |